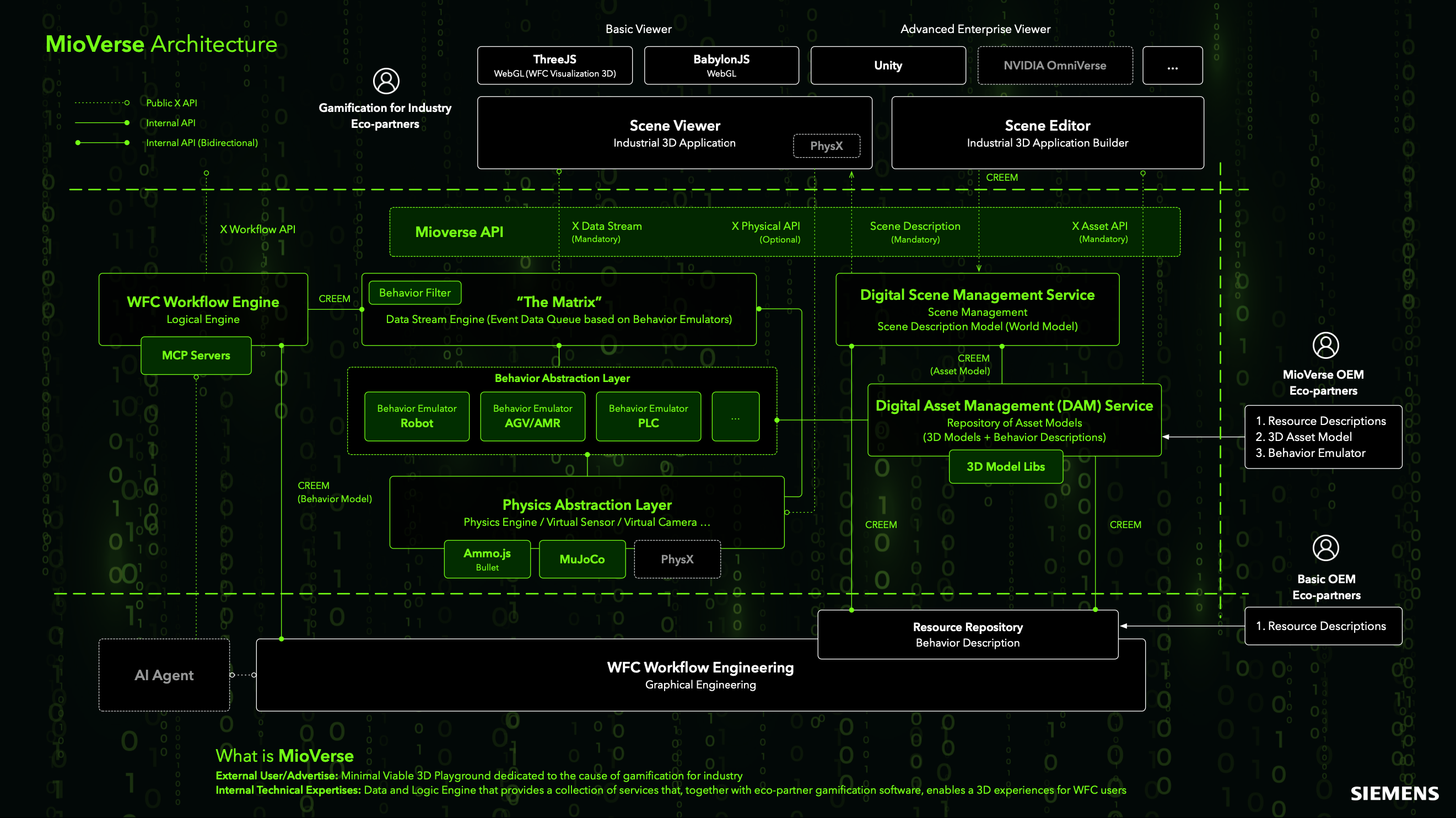

The diagram illustrates the MioVerse Architecture as a layered, service-oriented industrial 3D platform that integrates visualization, simulation, data streaming, and IT/OT workflow orchestration into a unified digital environment.

At the top layer, MioVerse supports multiple scene viewers and scene editors, ranging from web-based viewers such as Three.js and BabylonJS to advanced enterprise-grade platforms including Unity and NVIDIA Omniverse. These viewers consume standardized scene descriptions, asset definitions, and data streams to render and interact with industrial 3D applications.

The core integration layer is exposed through the MioVerse API, which provides mandatory interfaces for data streaming, scene description, and asset management, as well as optional physical APIs. This API layer decouples visualization clients from the underlying execution, data, and simulation services, enabling extensibility and ecosystem participation.

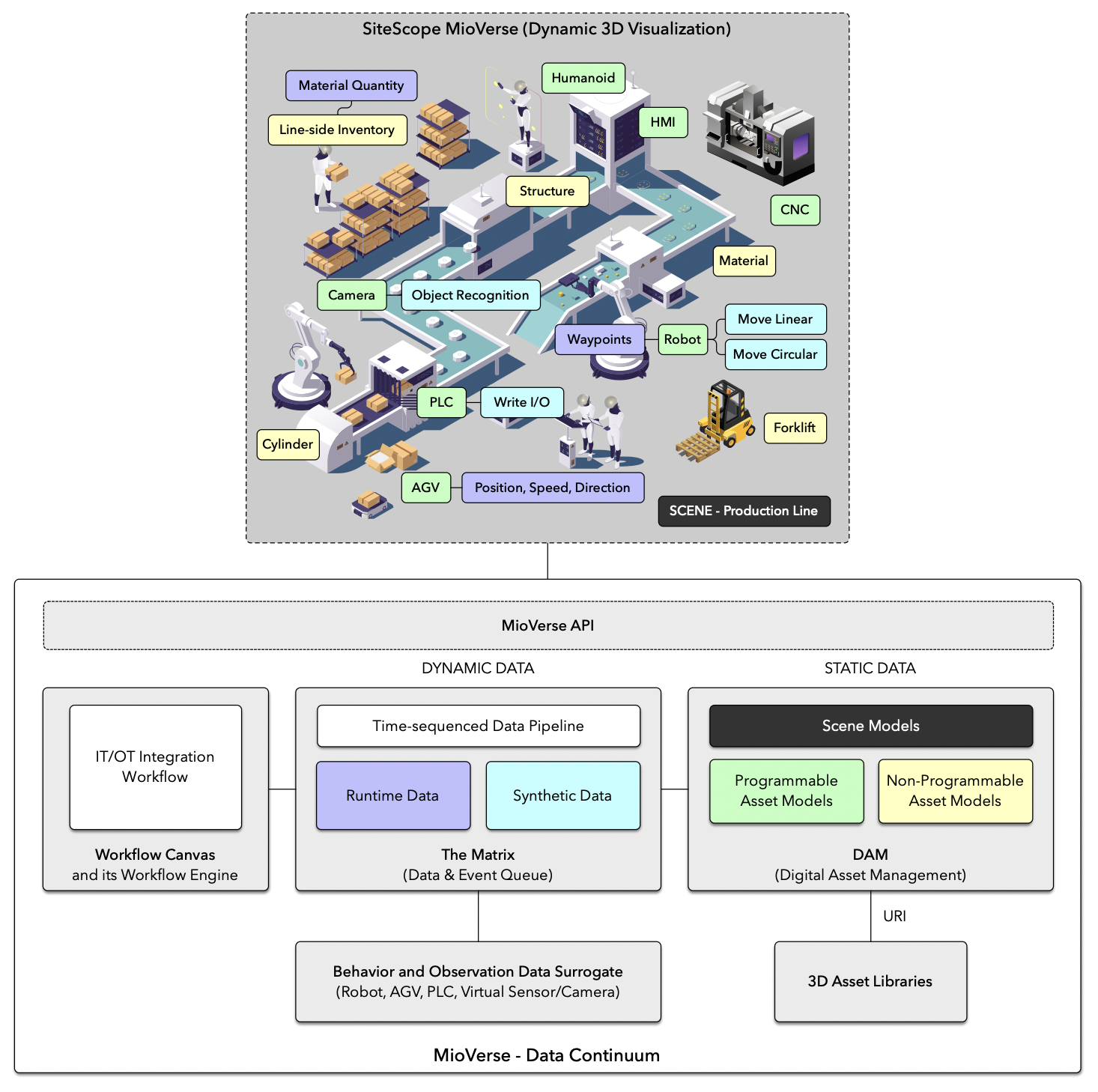

Dynamic behavior and event data are managed by "The Matrix", a centralized data stream engine that functions as an event-driven queue based on behavior emulators. It aggregates runtime signals produced by robots, AGVs/AMRs, PLCs, and other industrial entities through a dedicated behavior abstraction layer, ensuring consistent temporal sequencing and semantic alignment.

Beneath this layer, the physics abstraction layer integrates multiple physics engines and virtual sensing technologies, such as Ammo.js, MuJoCo, and PhysX, to support realistic motion, collision, and perception modeling. This allows physical behaviors and virtual sensors or cameras to be treated as first-class data sources.

Static and semi-static knowledge is governed by the Digital Scene Management Service and the Digital Asset Management (DAM) Service. These services maintain world models, scene descriptions, asset models, and associated 3D model libraries, linking structural definitions with reusable behavior descriptions via standardized resource identifiers.

On the orchestration side, the WFC Workflow Engine provides a logical execution environment for IT/OT integration workflows, while WFC Workflow Engineering enables graphical authoring and lifecycle management of behaviors and control logic. This layer also supports AI agents, enabling autonomous reasoning and interaction with industrial scenes.

Collectively, the MioVerse architecture establishes a scalable industrial metaverse foundation in which visualization, physics-based simulation, real-time data streams, and workflow-driven logic converge. This design enables ecosystem collaboration, digital twin realization, and gamified industrial experiences across both internal and partner-driven solutions.