Build IT/OT elements as self-evolving (autonomous) infrastructures, using Dynamic Behavior Modeling to represent industrial behaviors in natural-language semantics that both human and AI agents can un-derstand and use as services/tools.

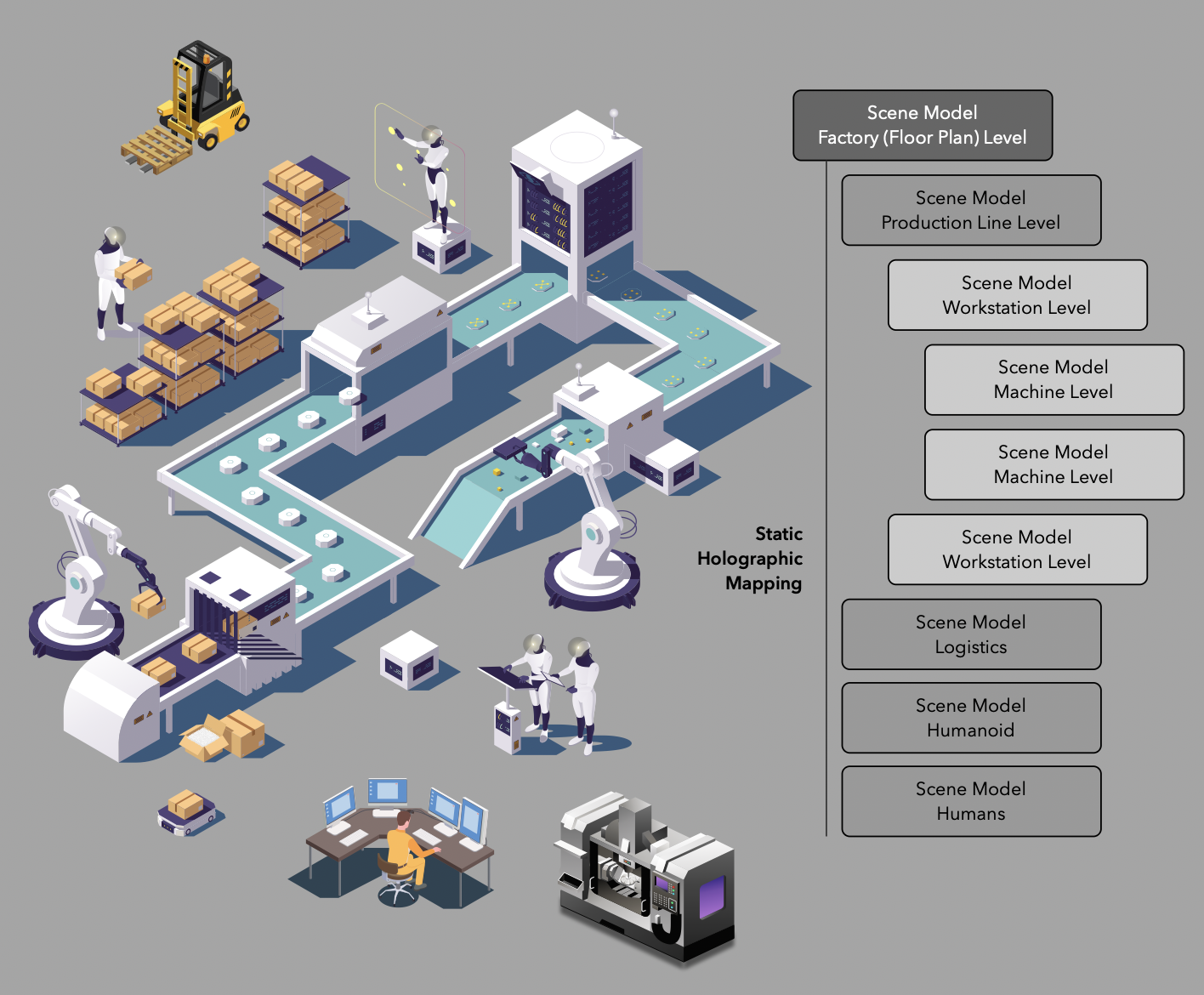

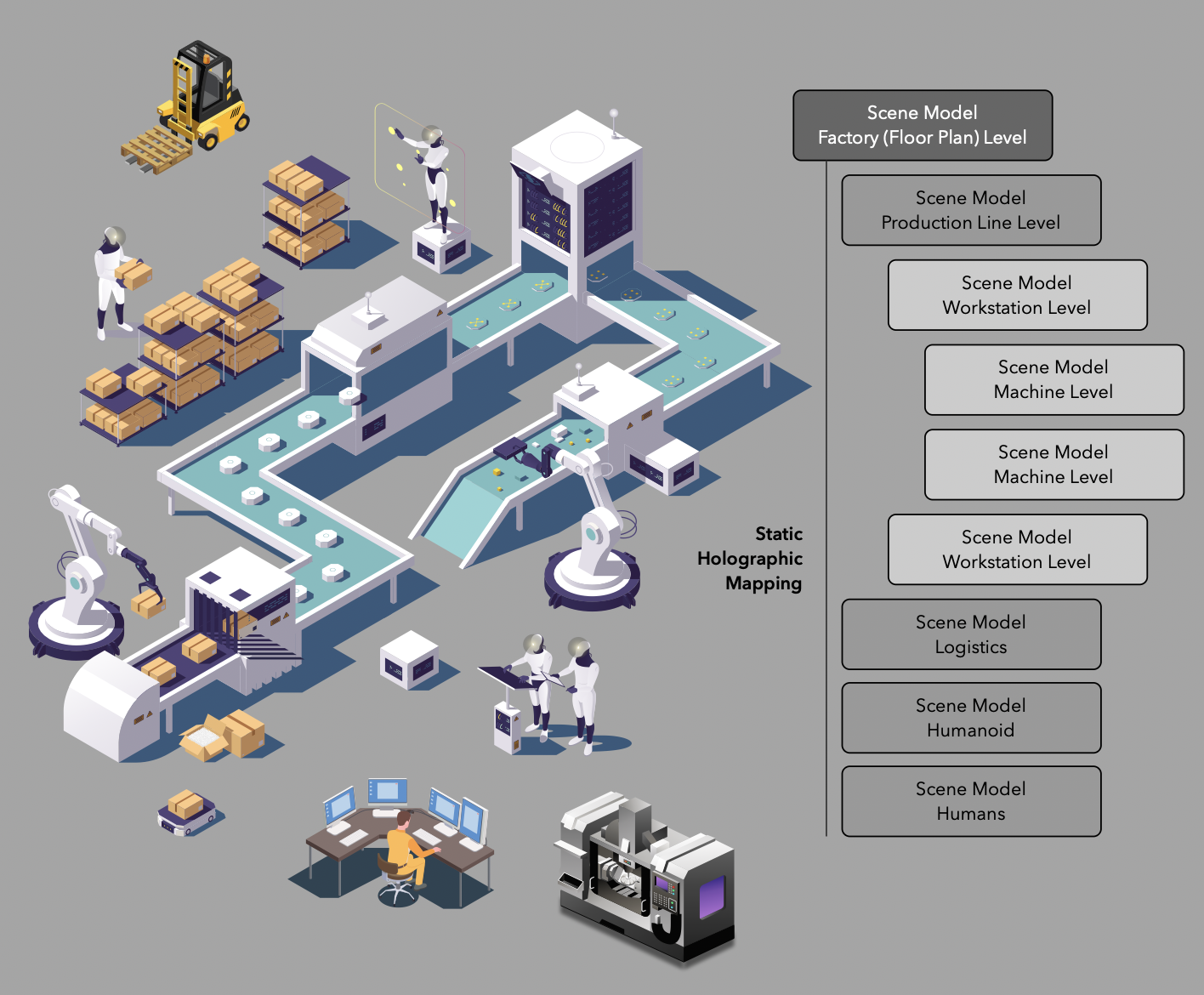

An industrial world model refers to a digital representation system that can uniformly describe an industrial system's spatial structure, physical objects, processes, and behavioral rules. Its core goal is, driven by multimodal data, to use artificial intelligence—automatically or semi‑automatically (human‑in‑loop)—to construct highly consistent, inferable, and exchangeable 3D scenes and semantic information models, and to support industrial data spaces and agent applications across domains such as manufacturing, buildings, and energy.

The industrial world model aims to build:

Research how to use multimodal inputs and AI technologies to drive world model construction. Core input sources for the world model include point clouds (LiDAR/SLAM), images/videos, CAD, 3D asset libraries, BIM, sensor data, device logs, SCADA/PLC data, production recipes, BOM, BOP, standard operating procedures (SOP), material flow, etc.

Research how objects, topological relationships, and behavior data in 3D scenes map to 3D modeling standard information models and industrial information model systems, as well as constructible and extensible standardized ontologies. Including but not limited to OpenUSD, 3MF, ISA95, ISA88, OPC UA, AAS, IEC 61850, MTP, Brick, SAREF, ECLASS, DPP and other standard systems. The goal is to make the world model both explainable to engineers and directly usable by AI agents.

Industrial world model research highly depends on datasets across industries and scenarios. Collaborative construction of the following categories of open or semi-open datasets for AI training and validation. These datasets form the training foundation of industrial world models, enabling AI learning beyond pure visual and geometric levels.

Typical Industrial Dataset Examples:

Overview: The physics engine and production cycle-time simulation are key components of the industrial world model, used to simulate the real motion behaviors of industrial equipment, robots, material flows, and manufacturing systems. The goal is to provide highly credible production dynamics in a virtual environment to support automation design, digital twin validation, AI agent training, process optimization, and anomaly prediction.

Key Technical Topics (to be supplemented):

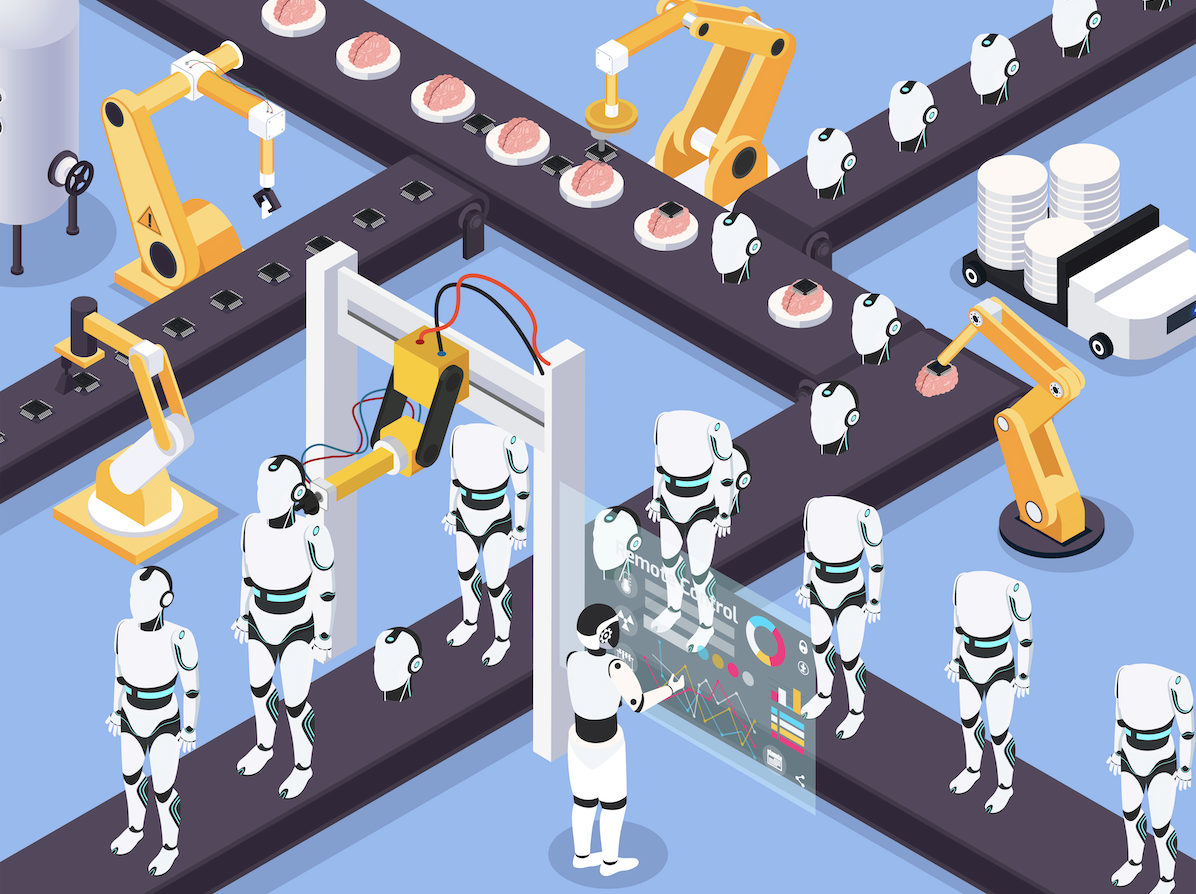

With the rapid development of artificial intelligence and robotics, embodied intelligence is increasingly becoming an important direction driving human–machine interaction, smart manufacturing, digital twins, and ubiquitous computing. Embodied intelligence emphasizes not only algorithmic intelligence but also interaction capabilities and behavioral performance in physical space. Therefore, establishing a unified general information and behavior model for embodied intelligence is significant for achieving interoperability and collaborative applications across industries, platforms, and devices.

This standard proposes a unified architecture for information and behavior modeling of embodied intelligence, defining metamodels, information (static) models, behavior (dynamic) models, and their respective interoperability requirements. By describing metamodel types and structures and security models, it forms an extensible modeling foundation; by semantically expressing information models and data exchange, it supports the description and static modeling of humanoid robots and their industrial contexts; and by dynamically abstracting behavior models and virtual simulation, it supports comprehensive dynamic modeling and reasoning for robot behavior trees, state machines, semantic layers, and agents.

The standard introduces domain-specific languages, communication protocols, and application specifications for operating systems and runtimes tailored to embodied intelligence, supporting standard interoperability methods for various humanoid robots across different domain scenarios.

To achieve interoperability among multi-source heterogeneous systems, the standard proposes interoperability mapping and compatibility mechanisms and integrates industrial and IoT standards such as AAS (Asset Administration Shell), DPP (Digital Product Passport), OPC UA (OPC Unified Architecture), and MTP (Module Type Package), supporting alignment and cooperation with existing robot-related standards (e.g., IEEE 1872 series, ISO/TC 299, IEC 61508/IEC 60748).

This standard is intended to provide a unified generic information and behavior modeling approach for embodied intelligence applications, improving semantic consistency, behavior orchestrability, system interoperability, and application extensibility, and to provide fundamental support for the research and deployment of future humanoid robots, industrial and collaborative robots, agents, and digital twins.