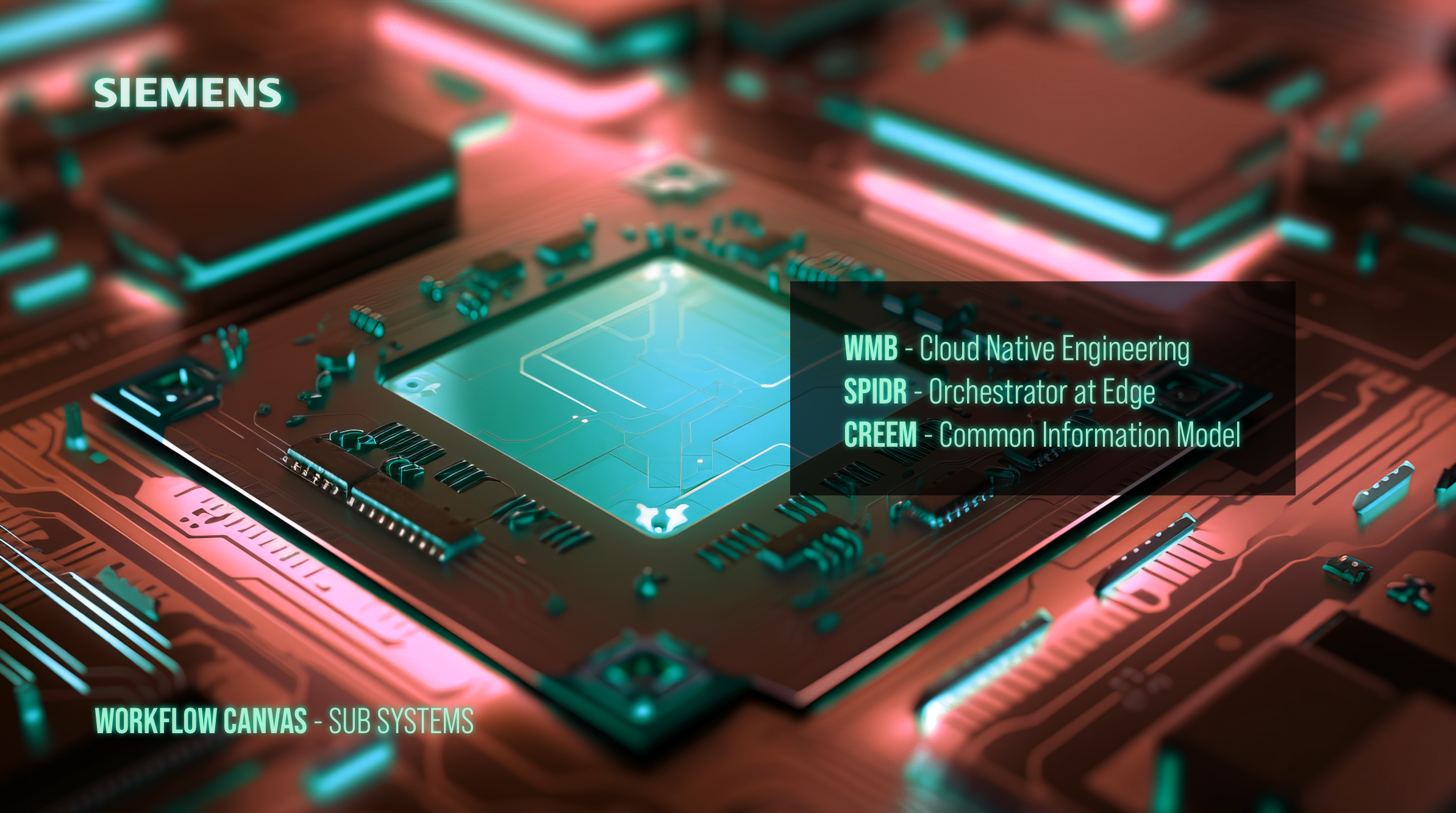

Workflow Canvas® 工易魔方™

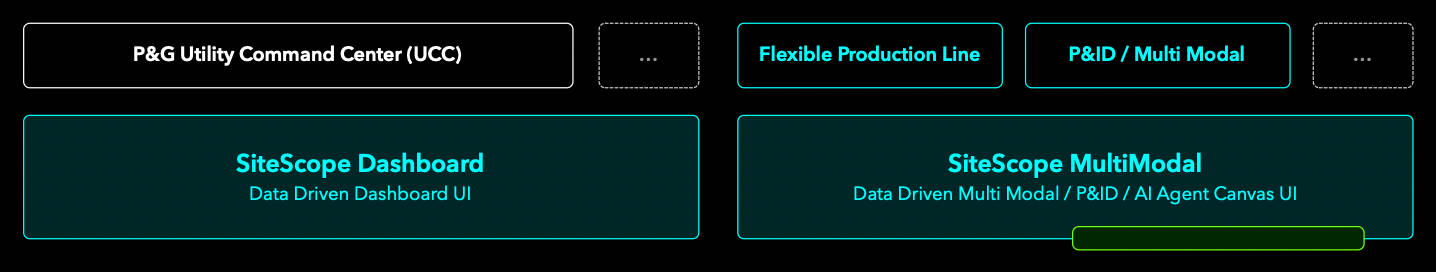

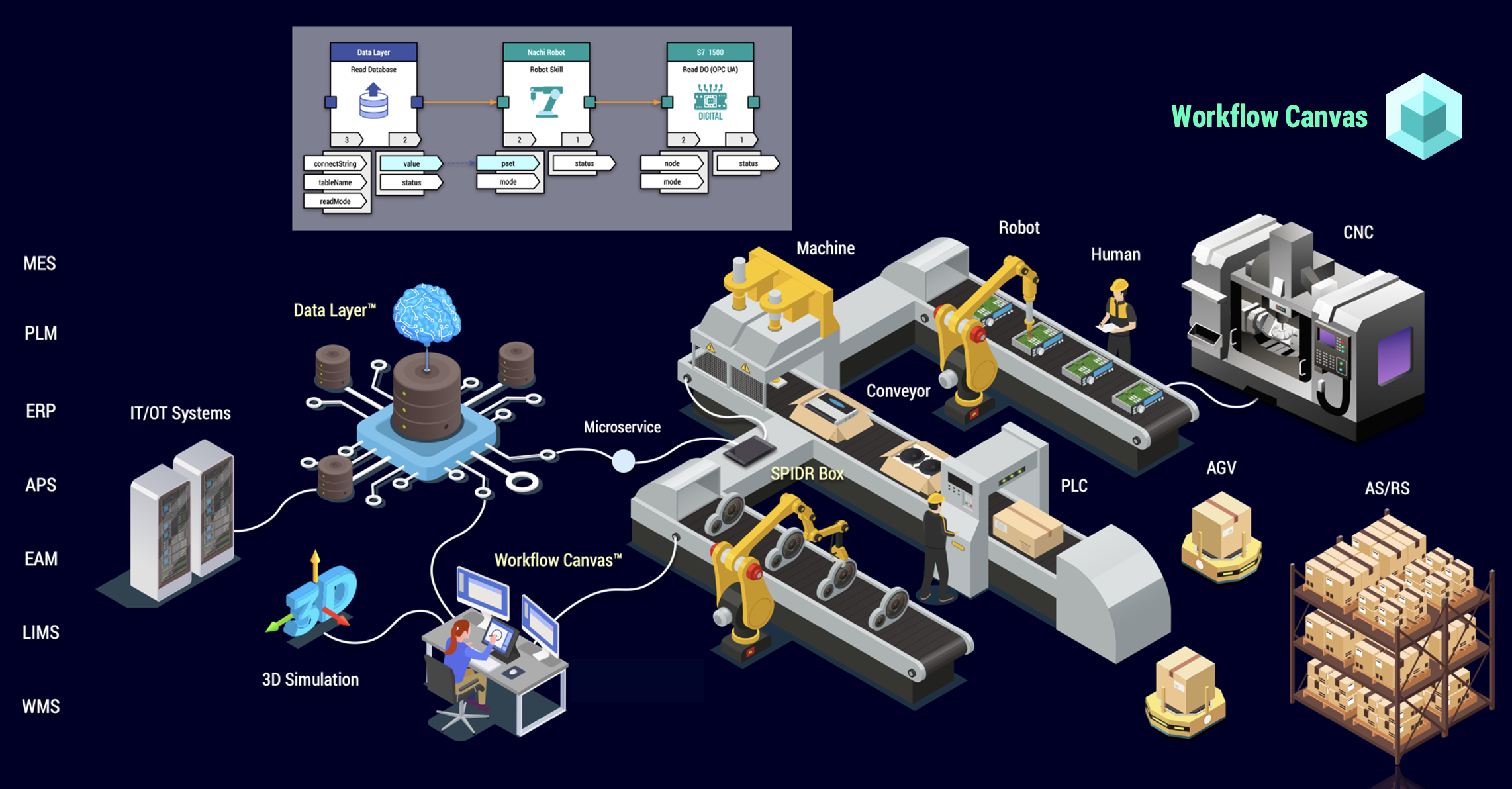

Workflow Canvas (WFC), a comprehensive development kit, empowers users to swiftly deploy flexible production lines and develop innovative industrial IOT applications. Central to its appeal, it propels enterprises towards a data-driven operational paradigm, ultimately optimizing efficiency and driving business growth.

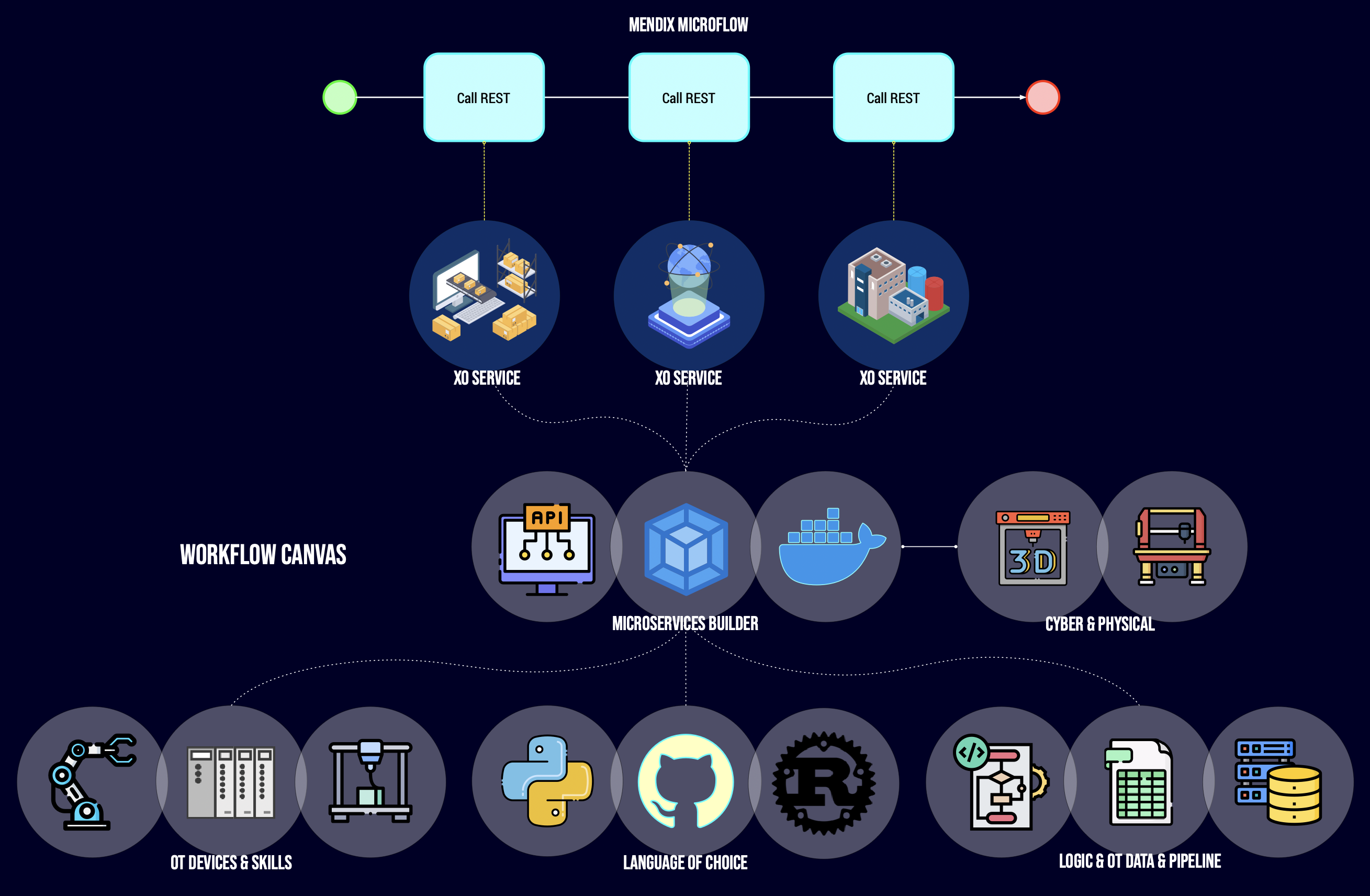

Workflow Canvas is a cloud-native IT/OT integration toolkit that enables Siemens and its eco-partners to develop integrated digital solutions faster, with web-based engineering, built-in 3D visualization, and container-based runtime ready to be deployed either on-premise or in the cloud.

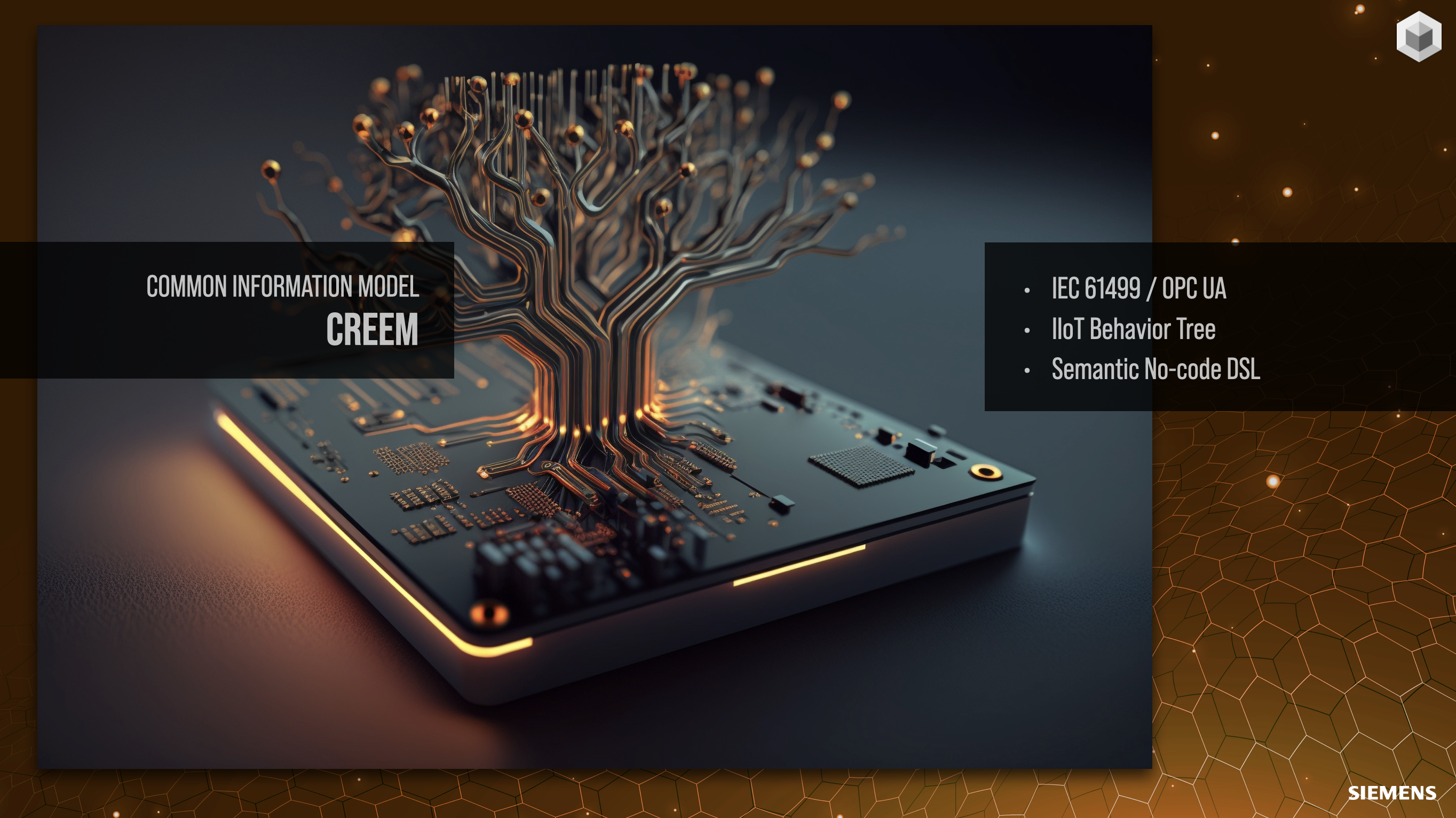

Its drag-and-drop interface provides an intuitive developer experience, while both IT and OT engineers can collaborate on the engineering of a plethora of devices, equipment and information systems. The resulting runtime is a cross-platform orchestrator (SPIDR) that comes with data integration options such as IIH and the Semantic Data Platform (SDP), offering highly flexible and customizable digital integration solutions to meet the rigorous demands of various industries.

Official Website: http://wfc.siemens.com